Global metal cutting technology leader Kennametal has joined the Nuclear AMRC to help develop innovative solutions for machining challenges across the low-carbon energy sector.

Kennametal creates some of the most innovative metal cutting tools and technologies in the world, for use in demanding applications like the growing low-carbon energy sectors including nuclear, renewables and waste-to-energy industries.

“The Nuclear AMRC is uniquely placed to provide access to the latest research and development in the low-carbon energy sector, and together, we believe our metal cutting expertise can make a real difference in the productivity and efficiency of manufacturers operating in this space,” said Werner Penkert, Manager Global Future Solutions Engineering, Kennametal.

“We’re looking forward to partnering with the Nuclear AMRC and its members to meet the needs of this growing sector through innovative products, proven machining solutions and deep application expertise.”

Fuelled by deep material science expertise and wide application experience across a vast range of metal cutting and shaping needs, Kennametal is a trusted problem solver. The company brings the tools, knowledge, and support to customers to deliver cost savings and higher productivity to drive success, no matter the challenge. With customers across many industries including the energy sector and with extensive experience in large component machining for power plant installations, Kennametal has been a leader in innovation and technology for more than 80 years.

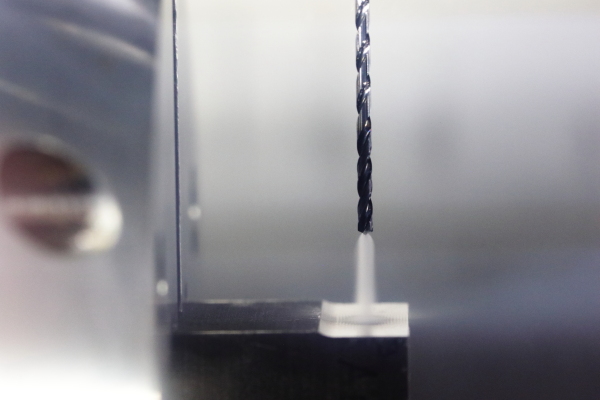

Cutting trials at the Nuclear AMRC using a Kennametal 3mm drill with internal delivery of CO2 coolant.

The Nuclear Advanced Manufacturing Research Centre (Nuclear AMRC), based at the University of Sheffield and part of the UK’s High Value Manufacturing Catapult, collaborates with companies of all sizes to help them innovate and win work in the nuclear supply chain.

As part of its tier two membership, Kennametal will support the Nuclear AMRC’s machining technology researchers to develop innovative and optimised machining processes for large high-value engineered components to help reduce manufacturing costs and lead times and improve overall operational efficiencies.

Dr Krystian Wika, Senior Technical Fellow at the Nuclear AMRC, said: “Kennametal brings some exciting and innovative solutions to support our machining research. We’re looking forward to working with them to tackle challenges such as the machining of refractory metals and other difficult-to-machine materials, and to apply new tooling designs and advanced cooling techniques to energy sector applications.

“By collaborating with Kennametal, we can put more tools in the toolbox to help the UK supply chain meet the manufacturing challenges of new reactors and other low-carbon technologies.”

- Find out more about Kennametal.