Welding technology specialist K-TIG will work with the Nuclear AMRC to develop innovative automated fabrication techniques for decommissioning waste containers.

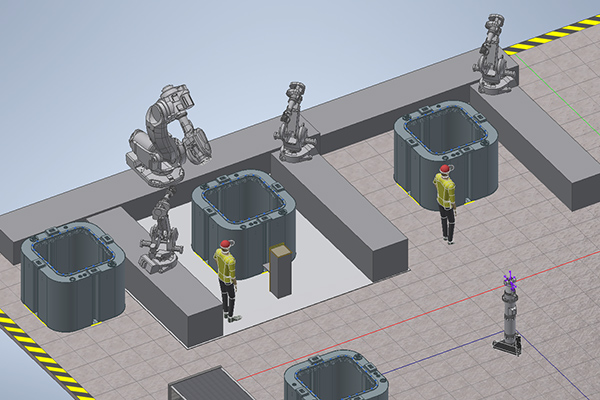

The Nuclear AMRC is developing a new technology demonstration facility at its Rotherham research factory which will integrate a range of state-of-the-art fabrication, monitoring and inspection techniques for waste container production.

The heart of the facility will be a robotic welding cell, which could be instrumental in the decommissioning of the UK’s legacy nuclear power sites. The centre will have the fabrication capability for the 3m3 stainless steel boxes used to safely store decommissioning waste.

These containers are critical for the successful and safe decommissioning of the UK’s nuclear power sites, and automated robotic fabrication using K-TIG’s welding technology is seen as key to meeting the exacting quality standards required.

The Nuclear AMRC’s technology demonstration centre will de-risk the fabrication process, and help UK manufacturers to modernise their fabrication capabilities and participate in the ongoing nuclear decommissioning programme.

K-TIG has now been selected as the preferred welding technology for demonstrating welding techniques for the Tranche 2 containers scheduled to be procured from 2024/25. Under a memorandum of understanding signed in September, K-TIG will work with the Nuclear AMRC to design, develop and supply the robotic welding cell that will fabricate these mission-critical containers.

Ben Hall, K-TIG’s general manager for the UK and Europe, said the initiative will underpin the upskilling of the UK fabrication industry and advanced welding applications, and create sustainable jobs for the future.

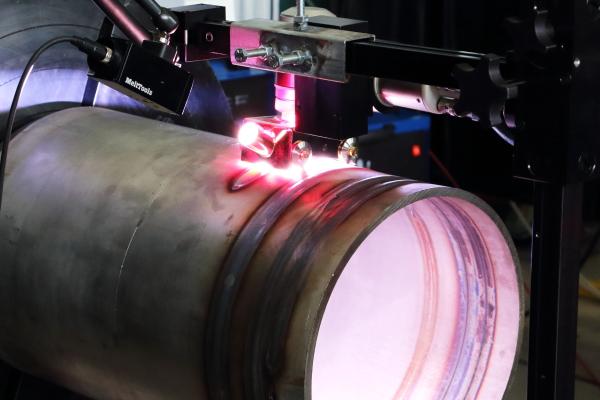

“Our research and development partnership with the Nuclear AMRC embodies Industry 4.0 and the UK factory of the future,” he said. “Working with the world leading nuclear research body Nuclear AMRC, the robotic welding cell will showcase the precision, quality and efficiency of advanced K-TIG welding solutions which incorporate cutting-edge keyhole technology, robotics and real-time quality assessment. It will fast become the standard for nuclear waste storage container welding.”

K-TIG joined the Nuclear AMRC as a member in December 2019 to collaborate on high-performance fabrication techniques for waste containers and other nuclear applications. Based in Australia, K-TIG has developed a patented keyhole welding technology which can produce welds 10–100 times quicker than conventional tungsten gas arc welding, joining metals up to 16mm thick in a single pass.

“The Nuclear AMRC and K-TIG will work together to further develop highly advanced methods to manufacture a range of products, including containers for the safe and secure storage of radioactive waste from the nuclear sector,” said Sean Murphy, strategic relationship manager at the Nuclear AMRC. “A successful conclusion to the collaboration would be to provide UK manufacturers with a turnkey solution for the fabrication of the products. This will help to ensure a strong supply chain, maintaining safe, repeatable quality and delivery.”

K-TIG will provide key equipment for the welding cell including the integrated welding automation, container manipulator, robotic welding arm and K-TIG welding systems, as well as the automated pre and post-weld inspection systems for real-time quality checking. K-TIG will also work with industry partners to integrate commercially available welding manipulators and robots, as well as ultrasonic, visual and acoustic sensor systems into the K-TIG controller to provide a turnkey welding cell for the fabrication of Tranche 2 containers.

K-TIG will fund the development of the welding cell for the Nuclear AMRC’s demonstration facility. K-TIG will maintain all commercialisation rights to the robotic welding cell, and make it available to the global nuclear waste containment fabrication industry.